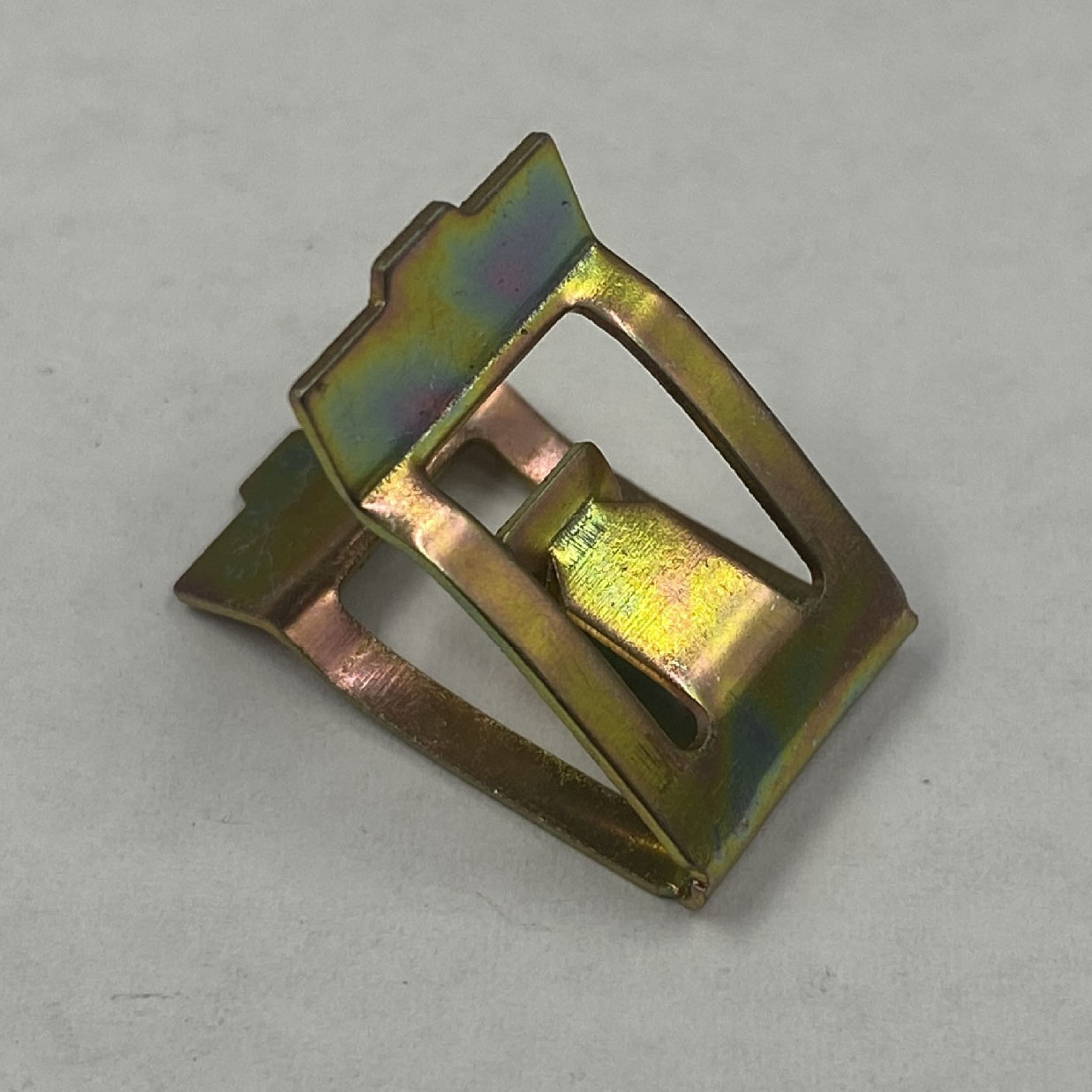

Labyrinth Seal

Send Inquiry

Labyrinth Seal is a type of seal that reduces leakage by incorporating numerous winding chambers between rotating and stationary components, representing an ideal labyrinth flow channel model. Its structure features multiple annular sealing teeth arranged sequentially around the shaft, with each tooth forming a series of flow-restricting gaps and expansion cavities. As the sealed medium passes through these winding labyrinth gaps, a throttling effect occurs, achieving the purpose of leak prevention.

Labyrinth seals are manufactured from steel or aluminum raw materials with diverse surface treatment options. Installation is rapid and straightforward, typically requiring no spindle rebuild. Often serving as the primary protective barrier, these seals help prevent bearing failures. Designed to shield high-precision bearings from rust, contamination, and debris, they contribute to eliminating bearing failures or unexpected maintenance issues.

Product Parameter (Specification)

|

Size |

Customized |

Material |

Stainless Steel,Carbon Steel,Aluminum |

|

Surface Treatment |

Natural, Electroplating, Oxidation,Polishing, |

Unit |

Piece |

|

Packing |

Bulk cartons with pallet or customized packing |

Lead time |

Peak season:20-30days Slack season:10-20days |

Product Application

Due to the clearance between the rotor and casing in labyrinth seals, there is no solid contact, eliminating the need for lubrication. This design accommodates thermal expansion and is suitable for high-temperature, high-pressure, and high-speed applications. Consequently, this sealing configuration is widely employed for shaft end seals and interstage seals in steam turbines, gas turbines, compressors, and blowers, as well as for front seals in other dynamic sealing arrangements.

Production Details