How do you know your goods have been dispatched successfully?

2025-10-24

Are you concerned about paying for goods that never arrive? Worried about damage during transit? Or perhaps anxious about shipment delays impacting your sales plans or project timelines? At Aoke, we eliminate these concerns through transparent dispatch procedures.

Once goods complete the entire production process and enter the dispatch preparation stage, we document every critical step and promptly share photographs with the relevant client.

During packing, we capture multi-angle photographs clearly showing each product's arrangement within standardised packaging boxes. Simultaneously, we implement protective measures against moisture and impact, enabling clients to visually assess packaging quality.

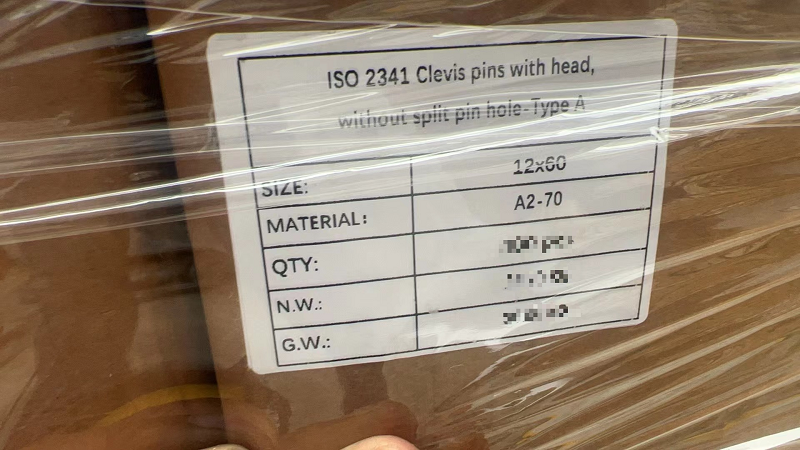

Upon completion of label affixing, we capture close-up photographs of the labels. These clearly display core details including client information, product model, quantity, destination, and shipping markings, providing precise guidance for subsequent warehousing, transhipment, and final delivery acceptance.

During loading, we photograph the process, documenting the orderly stowage of goods into containers or transport vehicles to confirm shipment commencement as scheduled.

These synchronised photographic and video materials are transmitted via channels specified by the client, such as email or instant messaging platforms. Clients can remotely monitor the entire process from packing to loading and dispatch in real time without needing to be physically present, clearly verifying the integrity of product packaging, accuracy of shipping markings, and timeliness of dispatch operations.